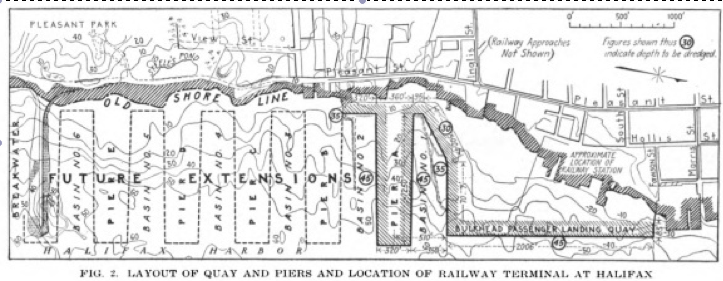

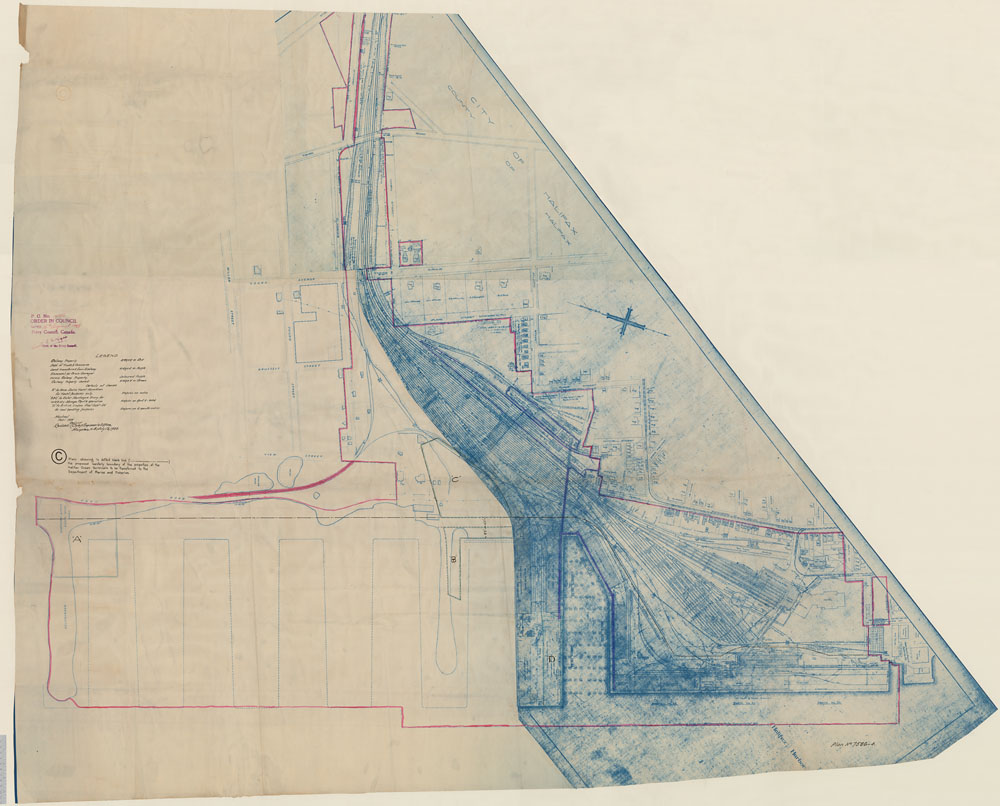

The Ocean Terminals were built in the south end of the city, close to the mouth of the harbour, and were meant to be new, modern and larger port facilities for Halifax. It was quite the civil engineering feat. The project was for the construction of what we know today as Piers 20-28, the railway cut, and port facilities.

Halifax for a while dominated as Canada’s East Coast port, but poor railway access made it too distant; and antiquated methods, unprofitable. In 1910, improvements were made to Pier 2 at the deep water terminus in the north end, however it was constrained by space available to it. Wharves, private residences and businesses had encroached, and there was no longer space for railway expansion. In 1912, the Dominion Government decided to proceed with the Ocean Terminals project.

Halifax for a while dominated as Canada’s East Coast port, but poor railway access made it too distant; and antiquated methods, unprofitable. In 1910, improvements were made to Pier 2 at the deep water terminus in the north end, however it was constrained by space available to it. Wharves, private residences and businesses had encroached, and there was no longer space for railway expansion. In 1912, the Dominion Government decided to proceed with the Ocean Terminals project.

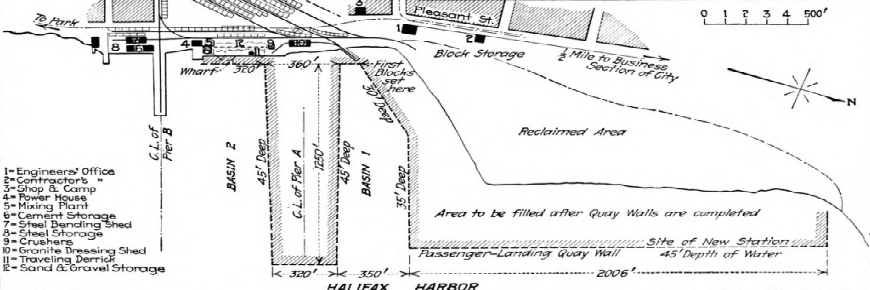

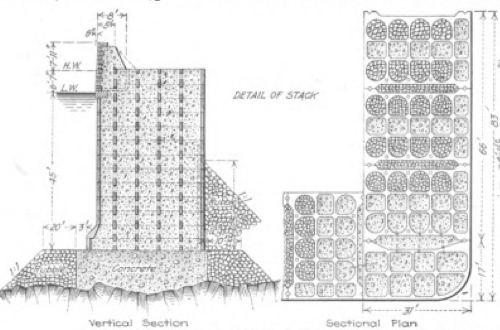

Though expected to be much larger, the initial project called for the construction of the passenger terminal, interconnected with the rail terminal, as well as Pier A, and the breakwater. The requirements were for 45′ depth.

The construction contract was held by Foley Bros, Welsh, Stewart & Fauquier. James Macgregor was the Superintending Engineer, responsible for design and construction for the Canadian Government.

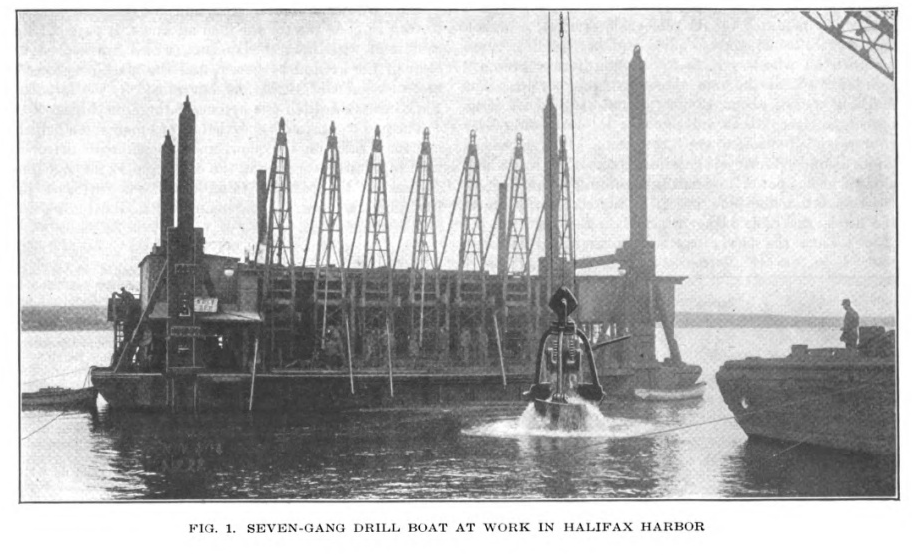

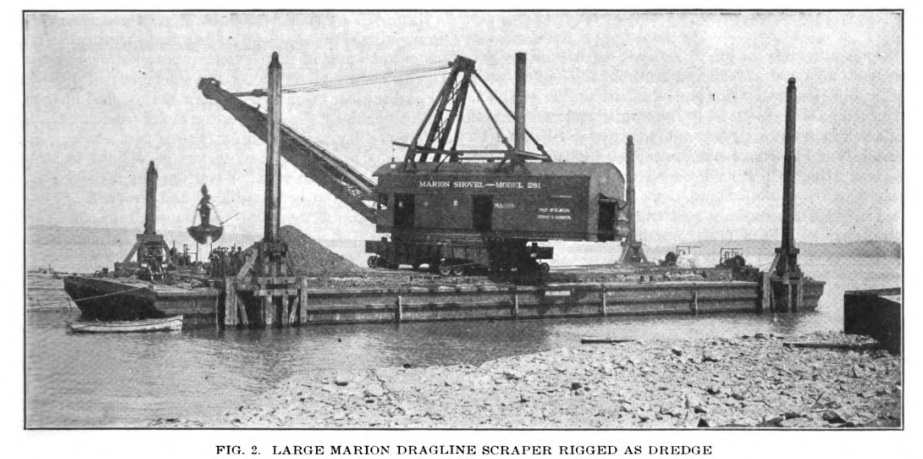

Though Halifax is known for having a deep natural channel, the piers were located close to shore; in places, in as little as 10 feet of water, and so required substantial dredging. 250,000 cubic yards of material was removed to ensure the required 45′ depth was met. As well, stable foundations would be required for the piers. The area would be drilled, charges set, and then the rock excavated. Most of the rock was excavated by the Canadian government’s 12yd dipper dredge “Cynthia”, though deeper areas were done with a Marion Dragline scraper on a barge fitted with an orange peel bucket. This crane was intended to be used for block placement, but proved versatile.

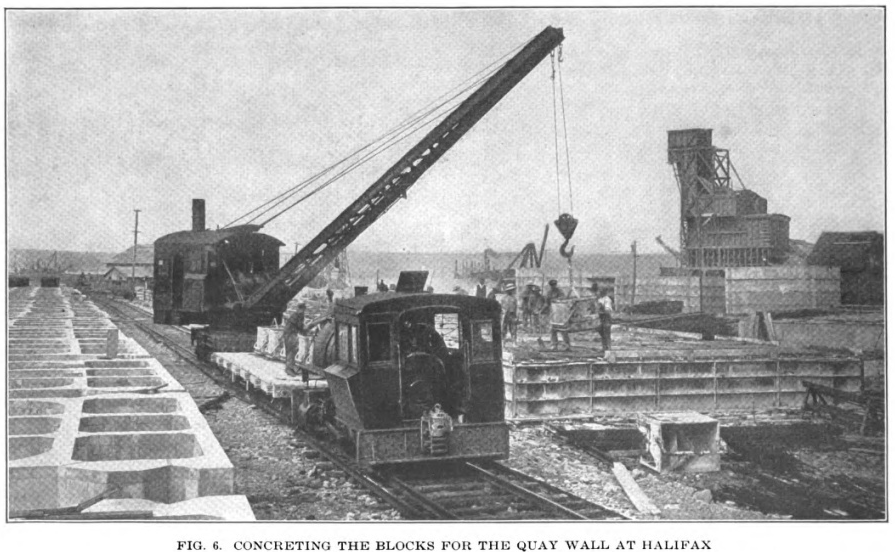

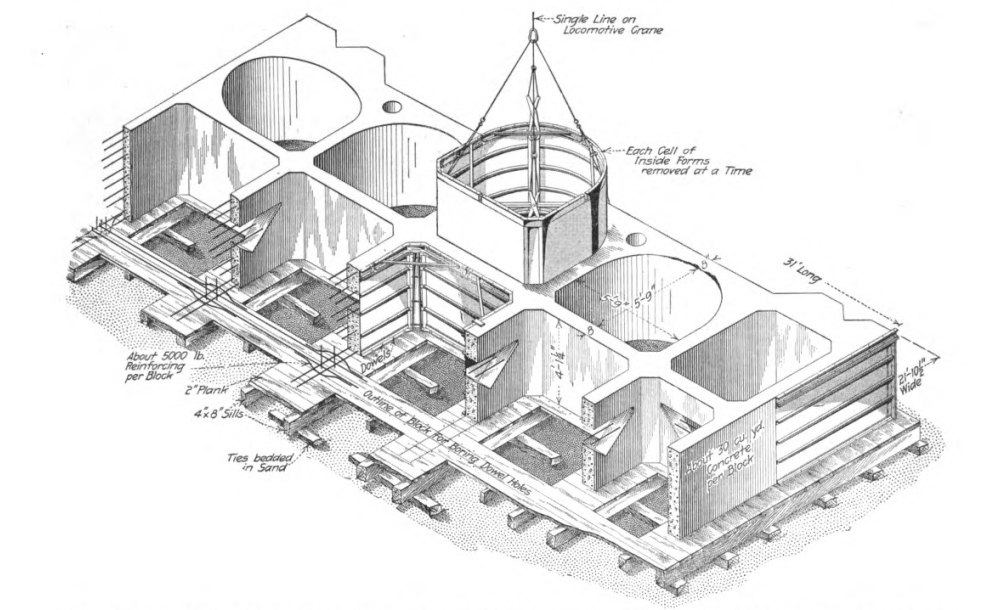

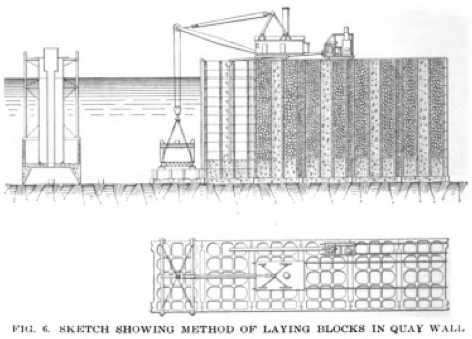

The pier was to be constructed from 3647 sixty-ton Concrete blocks would then be stacked to form the pier face, and then after placement filled with sand rocks and concrete. The area within would then be filled. The blocks were 31′ wide, 22’long and 4’tall. They were cast on site, and stored until they were required to be placed. Though this method was not new, it was to date the largest construction using this method.

A concrete batch plant was setup on site, and the blocks were produced using a forming system. Most of the blocks were identical, so they could be easily mass produced.

A concrete batch plant was setup on site, and the blocks were produced using a forming system. Most of the blocks were identical, so they could be easily mass produced.

The blocks were cast on site and stored until needed. When they were required, a 100ton crane would pick up the block, take it to the end of the pier and lower it into place. the blocks were cast with keys to ensure they aligned properly when placed.

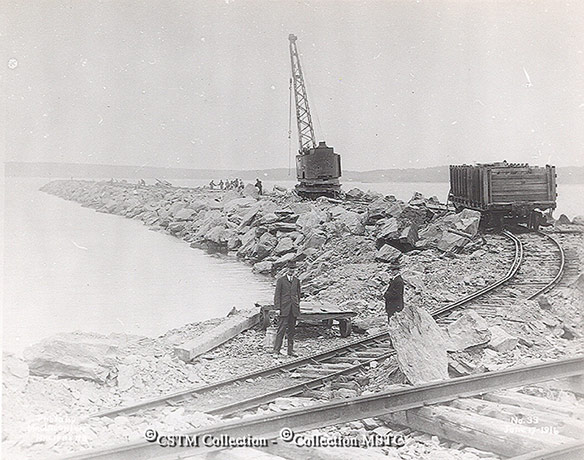

The breakwater was constructed with rock removed from the railcut. Loads of rock would be pushed out on railcars to the end of the breakwater, then across a plate girder bridge, and onto a barge. They would then be dumped. The barge was kept level in the tides by adjusting ballast. As the pier extended, the barge would be moved further along until the required 1500′ was constructed.

Once the piers were built, additional Facilities could be constructed. Pier A featured a sizeable freight shed, and the Terminal Shed at pier 21 was completed for handling passengers.

Once the piers were built, additional Facilities could be constructed. Pier A featured a sizeable freight shed, and the Terminal Shed at pier 21 was completed for handling passengers.